2025

Comparably’s Best Company Outlook

* Providing engineering services in these locations through SWCA Environmental Consulting & Engineering, Inc., an affiliate of SWCA.

From the experts we hire, to the clients we partner with, our greatest opportunity for success lies in our ability to bring the best team together for every project.

That’s why:

At SWCA, sustainability means balancing humanity’s social, economic, and environmental needs to provide a healthy planet for future generations.

SWCA employs smart, talented, problem-solvers dedicated to our purpose of preserving natural and cultural resources for tomorrow while enabling projects that benefit people today.

At SWCA, you’re not just an employee. You’re an owner. Everyone you work with has a stake in your success, so your hard work pays off – for the clients, for the company, and for your retirement goals.

Unpacking EPR Series: Why Extended Producer Responsibility (EPR) is Important to Brand Owners

EPR is a policy approach that shifts the responsibility for managing post-consumer packaging collection, logistics, and recycling from local governments to the producers.

Tristan has more than 25 years of experience collaborating with global consumer product and industrial manufacturing companies and other partners to address the practicalities of circular economy strategy and implementation.

Laura Nelson is an experienced leader and trusted advisor with over 18 years of experience in the environmental and sustainability services field. Laura has provided strategic sustainability services to clients in the food and beverage, consumer goods, manufacturing, technology, finance and energy industries. She has particular expertise in sustainability/ESG disclosure frameworks and standards, bolstered by a recent two-year position on the technical staff at the IFRS Foundation. Laura has also served as an Associate Director and facilitator for sustainability coalitions including the Beverage Industry Environmental Roundtable and the ISSB Technical Reference Group. As a Principal Sustainability Consultant, Laura provides clients with solutions that proactively address sustainability risks, recognize opportunities, build internal competency and governance of sustainability matters, and help navigate the complex sustainability disclosure landscape.

As explained in the first article of our Unpacking EPR series, several states have passed extended producer responsibility (EPR) legislation that requires producers to take responsibility for the end-of-life management of their products. EPR is a policy approach that shifts the responsibility for managing post-consumer packaging collection, logistics, and recycling from local governments to the producers. Compliance with these laws is essential in order to avoid legal penalties and continue operating in these markets.

EPR packaging laws are changing how packaging is handled throughout the supply chain, bringing significant challenges as well as creating opportunities for consumer goods companies. In this four-part series, we’ll simplify the complexities of EPR packaging laws in the United States and explain their impact on producers and brand owners. Next up: why EPR matters to brand owners.

To date, California, Colorado, Maine, Oregon, and Minnesota have passed EPR packaging laws. Each state is currently working to finalize the specific rules for these programs.

These EPR packaging laws require producers to pay fees based on the total of the distributed (sold) packaging. To manage compliance with this legislation, states assign producer responsibility organizations (PROs) to collect these fees and use them to improve recycling systems. Each state’s PRO or legislation determines the specific fee structure as a means to ensure an effective and sustainable approach to managing packaging waste.

The definition of “producer” varies from state to state but generally refers to brand owners or their licensees. For example, Minnesota’s law categorizes “producers” in a tiered manner to determine who is responsible for compliance. A producer is an entity that first brings “items sold in or with packaging” into the state. The “entity” could be physical retailers (brick-and-mortar stores) and/or those selling through e-commerce, remote sales, or distribution channels; or those who package items for shipment to retailers or consumers. The entity might be the “brand owner” of the product – meaning, packaging bears the name of the brand, and it was either manufactured by the brand owner or by another entity that packages the product on behalf of the brand owner (“licensee”). If the product packaging bears a brand name, the brand owner is the producer. Conversely, if the packaging does not display a brand name, or displays the name of the packaging manufacturer, the law considers the packaging manufacturer as the producer.

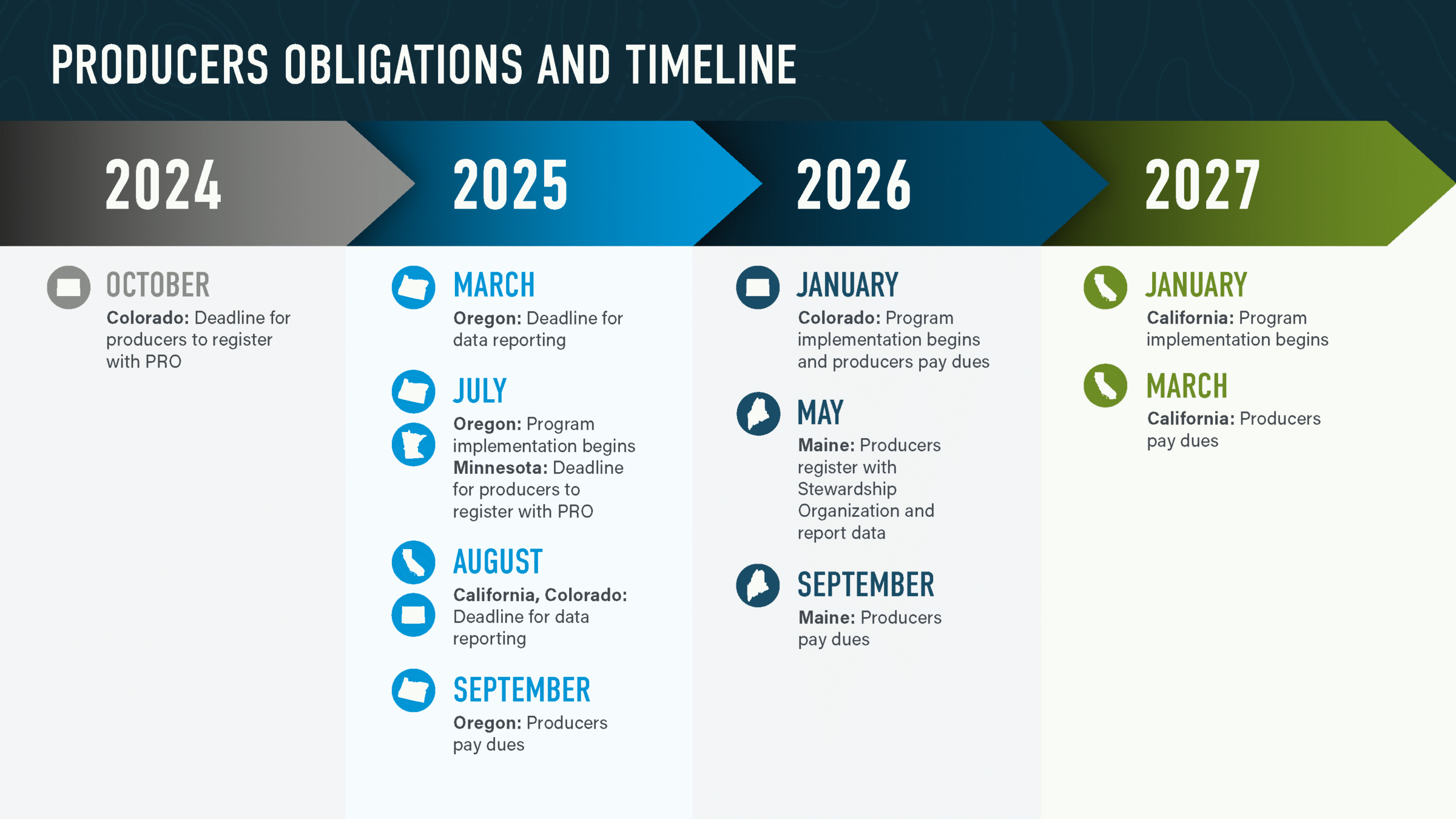

The Circular Action Alliance has outlined a timeline for each state to roll out its EPR packaging programs. It includes key deadlines for producers to either assign or join a PRO, complete state assessments, report sales or distribution data, and pay fees.

Producers’ first steps include registering with a state’s PRO and submitting the required data. Registration deadlines differ by state. For example, in Colorado, the deadline was October 1, 2024, while in Minnesota, it’s July 1, 2025. Deadlines for producers to submit EPR reporting data, like sales and packaging details, also vary by state. Oregon is first with a deadline of March 31, 2025, followed by Colorado and California later in the year.

For the most up-to-date extended producer responsibility (EPR) packaging legislation timelines, please refer to the Circular Action Alliance.

EPR packaging laws apply to many consumer products across different industries, though the rules can vary by state. Some exemptions exist, such as for small businesses, governments, and charities, but most single-use packaging is covered. To understand state-specific rules, the Sustainable Packaging Coalition offers a helpful tool on its website.

A key part of most packaging EPR legislation is the concept of “eco-modulation”, which incentivizes producers to explore more sustainable packaging designs. Eco-modulation means producers can pay lower EPR packaging fees if they make design improvements to their packaging to be more environmentally friendly. Examples include using post-industrial or post-consumer recycled (PCR) content or designing packaging that is easier to recycle after use.

As EPR packaging legislation continues to gain momentum, understanding and preparing for these changes is essential for producers and other members of the value chain. Our sustainability and management consulting experts at SWCA are at the forefront of EPR, circularity for consumer goods, and emerging sustainability compliance obligations. We’ve been leading the National Lubricant Container Recycling Coalition to accelerate the achievement of packaging recycling solutions for petroleum-based and related products in an industry that previously had no system for packaging recycling. SWCA is ready to help you navigate the compliance process, make the business case for your sustainability efforts, facilitate collective action, and drive the circular economy.

We invite you to stay tuned to our Unpacking EPR article series as we share more insights on EPR packaging laws and how producers can prepare for compliance.